Mechanizing Makhana Popping Saves the Health of Millions and Improves the Livelihood of Makhana Growers

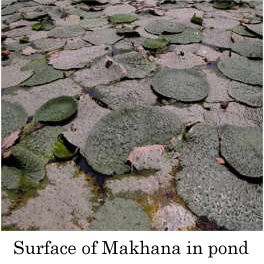

Gorgon nut or makhana is a seed of an aquatic plant grown mainly in Bihar, Assam, West Bengal, Tripura and Odisha. In Bihar alone it is grown in about 15000 hectare water-body and the Govt of Bihar has set target to increase this area to 20000 hectare by 2020. About five lakh families are directly involved in makhana cultivation, its harvesting, popping, and produce selling. About 7500- 10,000 tons of popped makhana is sold every year from Bihar. The seeds are roasted and popped manually to obtain a nutritious dry fruit popular in India and across the world. The commercial name of the popped kernel of Gorgon nut is makhana. Makhana is very popular among Indian households for making, vegetable curry, sweets and savories of various kinds and for religious rituals.

Traditionally makhana seeds have been popped manually. Popping makhana is a laborious, time intensive and cumbersome process. In a 3 stage manual process the seeds are roasted in traditional earthen pots or in cast iron pan at very high temperatures ranging from 250 to 320 oC, tempered for 2 to 3 days, roasted again and popped manually using a mallet. Malleting after roasting requires highly skilled workers because few seconds delay in malleting will result in poor quality popped makhana. Open fires by burning wood and agricultural wastes are used for roasting purposes. The works toil all day long in front of the open fire and at such very high temperatures for roasting and manually popping the seeds. Manual malleting causes burning injury in one hand and boils in other. If the worker is not skilled then the quality of roasted makhana will be poor resulting in huge monetary losses. Experienced poor fishermen in makhana growing areas are employed for such cumbersome operations.

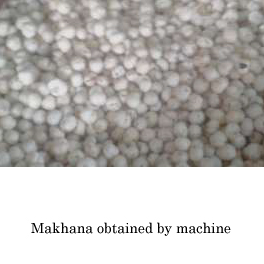

To save these poor fishermen from the toil and drudgery, to improve upon their working conditions and to produce high quality makhana for domestic consumption and export markets a completely mechanized system for roasting and popping operations have been developed and commercialized by ICAR. This system was developed by the ICAR’s Central Institute of Post-Harvest Engineering and Technology (CIPHET) located at Ludhiana. The mechanized model developed by ICAR has *roasting and popping unit. The roasting is done in closed barrel using electic heated thermic oil. Thermally insulated barrel saves the worker from intensive heat and malleting does not require at all as hot roasted seeds automatically hit a closed casin within seconds to break the hard roasted seeds for popping. There is no human intervention between roasting and popping, so the developed system completely saves the operators from intensive heat and boils in their hands.

This system further reduces the process time from 2 to 3 days to only about 20 h. The capacity of the popping operation has been increased by about 8 times. The quality and market value of makhana produced using the mechanized process is much better than the manually popped makhana. This machine is now being commercially manufactured and has been installed in several makhana growing areas. Makhana has traditionally being grown only in eastern and north eastern states of India. Due to the intervention of mechanically popping makhana entrepreneurs in other regions of the country like Madhya Pradesh, Himachal Pradesh, Telangana and Uttar Pradesh have shown interest in venturing in makhana trading, value addition and marketing.

The machine was launched on December 03, 2013 by Research Centre for Makhana Darbhanga, Bihar. Demonstrations and trainings were conducted in Darbhanga and Madhubani districts of Bihar. Entrepreneurs from Madhubani, Saharasa (Bihar), Indore (MP), Lucknow, UP have purchased the machine commercially and thus the technology has solved a long due indigenous problem of manual popping of indigenous crop. A full line comprising threshing, cleaning, drying, grading, roasting and popping is being established at CIPHET Ludhiana for training and demonstration purposes. The capacity of popping increased 8-10 times with better quality of makhana and income has also increased in the same proportion, which in turn improving their living standards. Looking the requirement and success of the technology Government of Bihar has started giving subsidy and National Research and Development Corporation (NRDC), Govt. of India has given the Societal Innovation Award in 2014. Economic analysis of about Rs. 15 lakh investment as fixed cost and about Rs. Five lakh as working capital per month, indicates that breakeven point will reach in 6 months and profit will be many folds, besides giving employment to rural youth. Mechanization of makhana popping process will increase cultivation area and thus production of makhana seeds, which ultimately will improve the livelihood of poor community engaged in makhana cultivation and processing in very near future. It is a blockbuster technology of CIPHET, Ludhiana and thus someone among the users has rightly named it “Vardan”. It is a true example of make in India.

After this development, ready-to-constitute makhana kheer (milk based pudding) mix was developed from the second or third grade of makhana. The mix does not requires cooking; and pudding can be prepared in a minute just by adding water and stirring is also getting ground. Three entrepreneurs again from Darbhanga, Bihar, Buddi in Himachal Pradesh and Rajendra Nagar, Hyderabad, Telangana have taken license for manufacturing and marketing. If an entrepreneur involved in popping also manufacture and market ready-to-reconstitute instant makhana kheer mix, net profit may be in the range of 5 – 10 lakh per month.

In this way a successful value chain of indigenous crop using indigenous technology is in place and has put momentum in further research. It has really solved a rural problem of cultivation of makhana in Bihar and North-east states of India.

Demonstration of makhana popping machine at Rahika, Madhubani by Makhana Research Centre, Darbhanga, Bihar